The Bessemer Process - Definition, Examples, Quiz, FAQ, Trivia

Discover how steel transformed the world during the Industrial Revolution

What is the Bessemer Process?

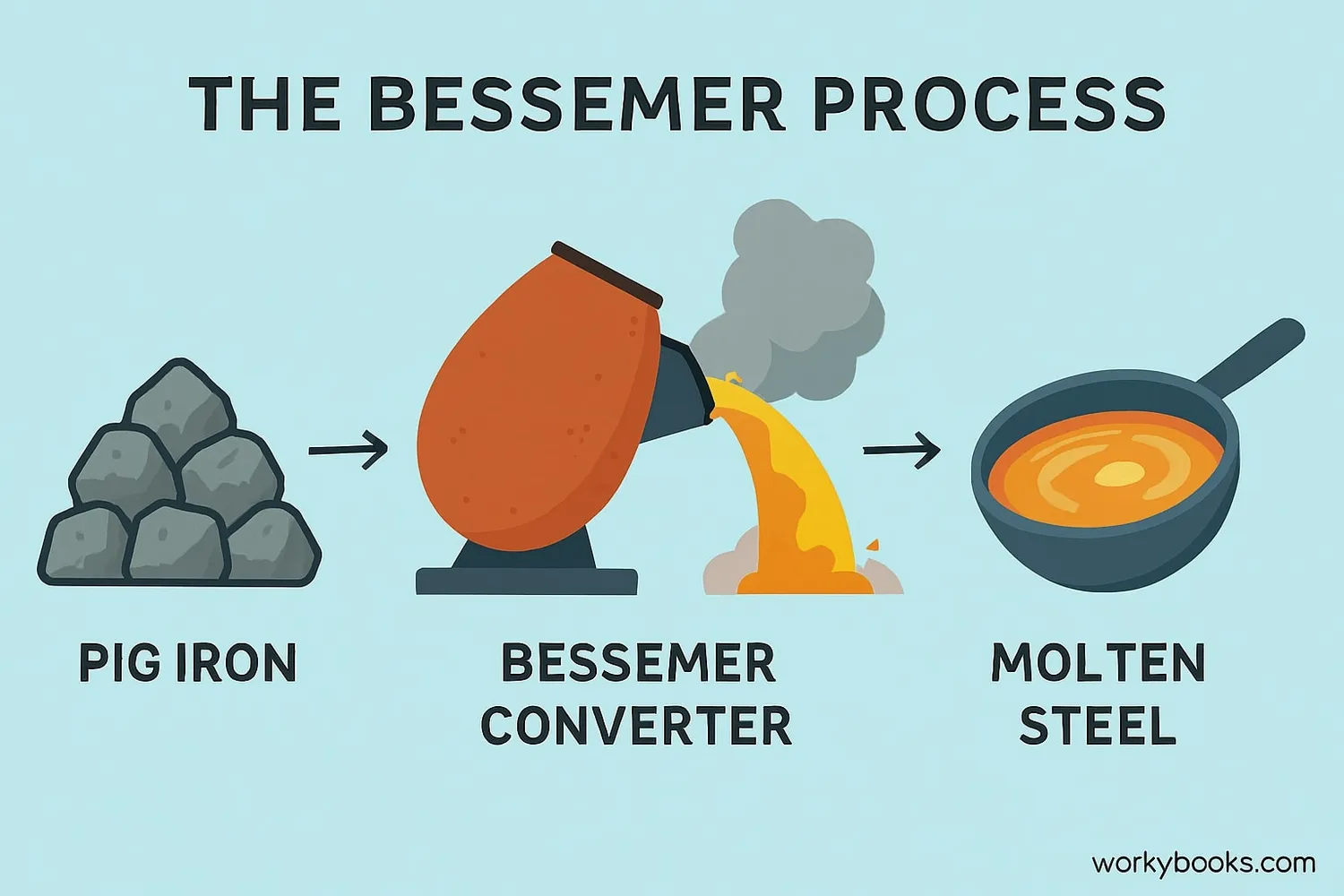

The Bessemer process was a revolutionary method for making steel invented by Sir Henry Bessemer in the 1850s. Before this process, steel was expensive and difficult to produce in large quantities. The Bessemer process made it possible to create high-quality steel quickly and affordably.

Steel is a special type of iron that contains a small amount of carbon. The Bessemer process removes impurities from molten iron by blowing air through it. This burns away extra carbon and other unwanted elements, turning iron into strong, flexible steel.

Historical Fact!

The Bessemer process reduced the cost of making steel by 80%, making it affordable for railroads, bridges, and skyscrapers!

How the Bessemer Process Works

The Bessemer process happens in a large container called a converter. Here's how it works step by step:

Iron Preparation

Iron is melted in a blast furnace at very high temperatures (over 1,500°C)

Converter Loading

Molten iron is poured into the Bessemer converter

Air Blowing

Air is blown through the molten iron from the bottom

Impurity Removal

Oxygen in the air burns away impurities like carbon and silicon

Steel Formation

The purified iron becomes steel, which is poured into molds

The chemical reaction that happens during air blowing is:

Impurities + Oxygen → Oxides (removed as gas or slag)

This entire process takes only about 20 minutes, which was incredibly fast compared to previous methods!

Temperature Fact!

The converter gets so hot during the process that it glows bright orange, reaching temperatures of about 1,600°C (2,900°F)!

Why the Bessemer Process is Important

The Bessemer process transformed the world in many important ways:

Railroad Expansion

Affordable steel allowed for thousands of miles of railroad tracks to be built

Skyscrapers

Steel frames made tall buildings possible for the first time

Industrial Growth

Factories and machinery could be built stronger and cheaper

The impact of the Bessemer process:

• Made steel affordable for the first time in history

• Reduced production time from days to just 20 minutes

• Enabled the construction of modern cities and infrastructure

• Created new jobs and industries

Before the Bessemer process, steel was so expensive that it was only used for small items like knives and tools. After Bessemer's invention, steel became the backbone of the modern world!

Bessemer Process Quiz

Test your knowledge about the Bessemer process with this quiz. Answer all 5 questions to see how much you've learned.

Frequently Asked Questions

Here are answers to common questions about the Bessemer process:

Fun Steel Trivia

Discover some fascinating facts about steel and the Bessemer process!

Massive Production

The first Bessemer steel plant in Sheffield, England could produce more steel in a week than previously made in a year using older methods!

Extreme Heat

The Bessemer converter reaches temperatures of about 1,600°C (2,900°F) - hot enough to melt iron and burn away impurities!

Skyscraper Revolution

The first steel-framed skyscraper was the Home Insurance Building in Chicago, built in 1885. It was 10 stories tall - revolutionary for its time!

Recycling Champion

Steel is the most recycled material in the world. About 88% of steel is recycled, and it can be reused endlessly without losing quality!