Malleability - Definition, Examples, Quiz, FAQ, Trivia

Learn how materials can change shape without breaking

What is Malleability?

Malleability is a material's ability to be hammered, pressed, or rolled into thin sheets without breaking or cracking. It's one of the special properties that makes metals so useful for creating objects.

Imagine playing with clay - you can press it flat into a pancake shape without it breaking apart. That's similar to how malleable metals behave! Materials with high malleability can be shaped into many different forms without losing their strength.

Malleability vs Ductility

Malleability is about shaping into sheets, while ductility is about stretching into wires. Gold is both highly malleable and ductile!

Examples of Malleable Materials

Gold

Most malleable metal - can be hammered into sheets thinner than paper

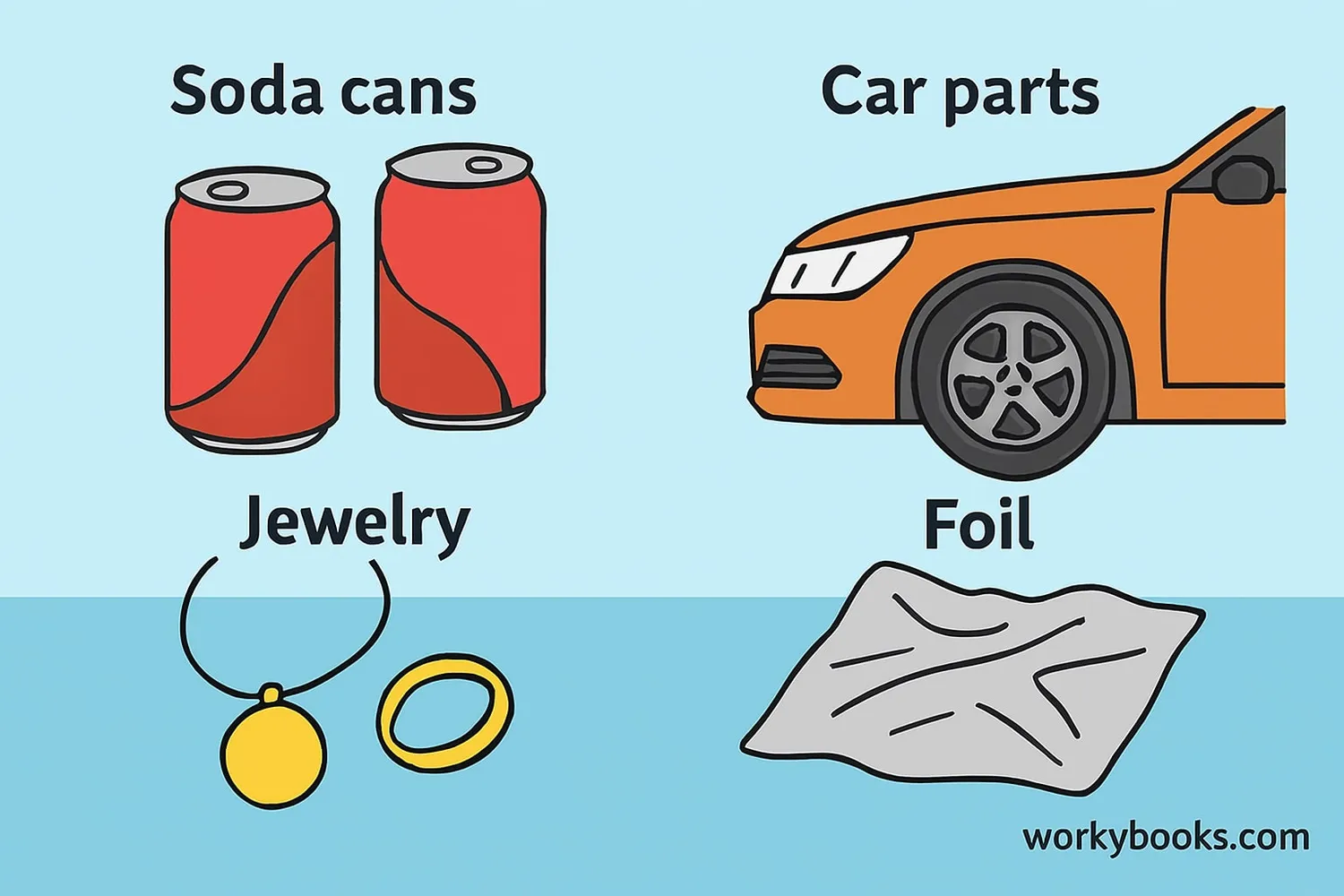

Aluminum

Used for foil, cans, and packaging materials

Iron & Steel

Shaped into car bodies, beams, and construction materials

How Malleability Works

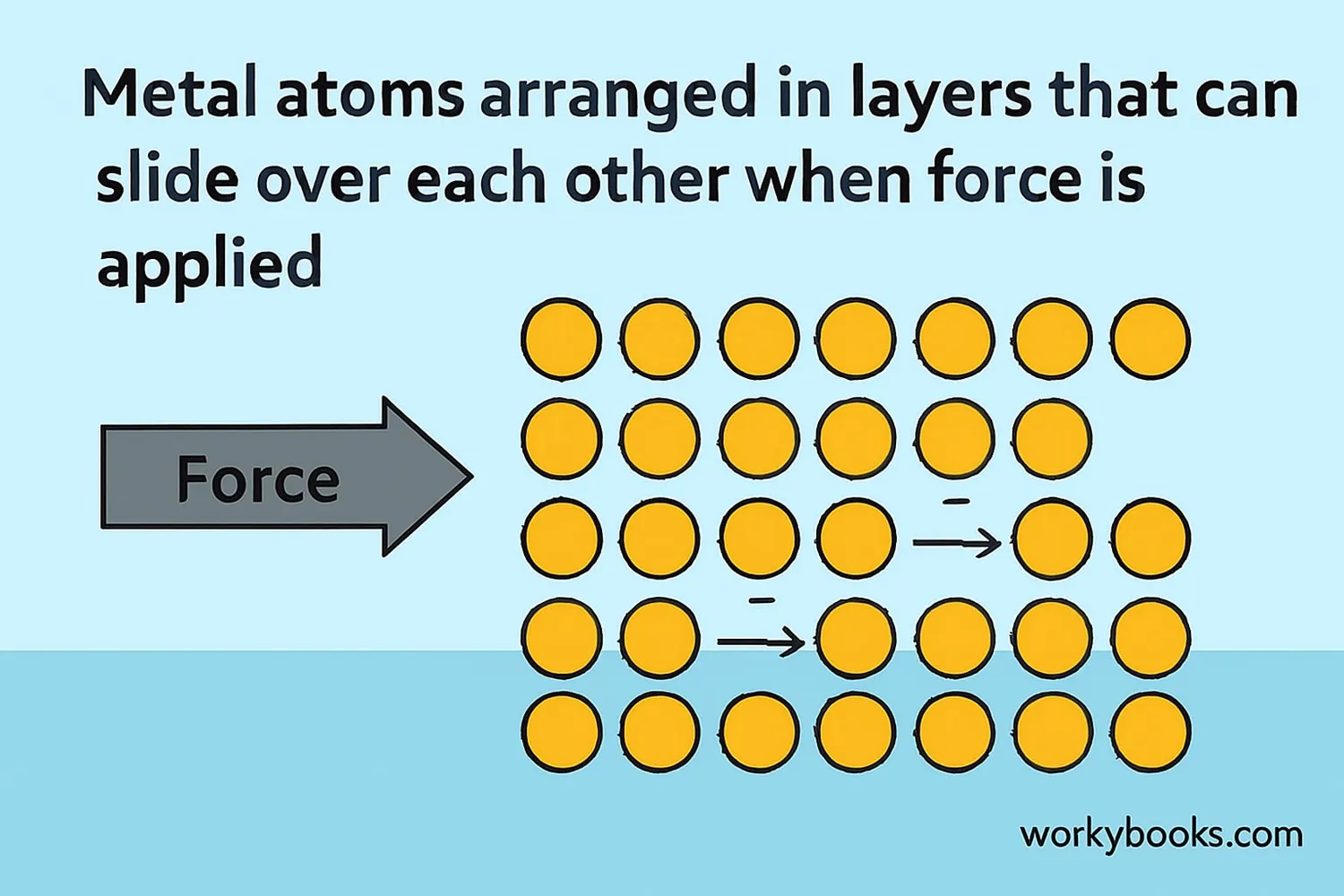

Malleability works because of how atoms are arranged in metals. Unlike materials like glass or ceramics that have rigid structures, metals have atoms arranged in orderly layers that can slide past each other when force is applied.

This special arrangement is called a metallic bond. The atoms share electrons that act like glue, holding the metal together while allowing the layers to move. When we hammer or press metal, these layers slide over each other, changing the metal's shape without breaking it.

Atomic Structure

Atoms arranged in orderly layers

Metallic Bonds

Shared electrons allow movement

Applied Force

Hammering or pressing applies pressure

Sliding Layers

Atomic layers slide past each other

New Shape

Material changes form without breaking

Material Comparison

| Material | Malleability | Common Uses |

|---|---|---|

| Gold | Very High | Jewelry, electronics |

| Aluminum | High | Foil, cans, aircraft |

| Copper | High | Wires, pipes |

| Glass | None | Windows, containers |

| Ceramic | None | Dishes, tiles |

Why Malleability Matters

Malleability is one of the most important properties in material science and manufacturing. Without malleable materials, many of the objects we use every day wouldn't exist!

Manufacturing

Cars, airplanes, and appliances are shaped from metal sheets

Construction

Metal roofing, structural beams, and pipes

Packaging

Aluminum foil and cans preserve food

Material Science

Engineers test materials to understand their malleability before using them in products. The ability to shape metal without weakening it is crucial for safety in buildings and vehicles.

Malleability allows us to:

• Create thin sheets for packaging

• Shape metal into complex forms

• Manufacture products efficiently

• Recycle materials by reshaping them

Without malleable materials, our world would look very different - no cars, no skyscrapers, and no aluminum foil for wrapping sandwiches!

Malleability Quiz

Test your knowledge about malleability with this quiz. Choose the best answer for each question.

Frequently Asked Questions

Here are answers to common questions about malleability:

Material Science Trivia

Discover fascinating facts about malleability and materials:

Gold Leaf

A single ounce of gold can be hammered into a sheet covering 100 square feet! Gold leaf can be as thin as 0.000127 millimeters.

Ancient Metalworking

Humans have been hammering metals into shapes for over 8,000 years! The oldest known gold jewelry dates back to 4600 BC in Bulgaria.

Mercury Mystery

Mercury is the only metal that's liquid at room temperature. While we don't hammer it, mercury shows high malleability by easily changing shape!

Aircraft Aluminum

Modern airplanes use special aluminum alloys that balance malleability for shaping with strength to withstand flight pressures.